The DSL-50 is a (Drop Style) destacking PCB line loader that can hold up to 80 PCBs. This system provides an intelligent pathway between machines via SMEMA interface and uses several PLC timers to track PCB progress and machine sequence. Both "Load" and "Pass" modes are available. A hand crank is used to adjust rail width. Roller wheels and leveling feet allow for quick integration into the line.

SIGNATURE FEATURES: Programmable Logic Controller. Single drive conveyor (Load / Pass modes). Adjustable for PCB thickness. Transport speed (180mm/sec - Fixed) – (variable speed optional). Dual E-Stops (Optional)and master On / Off switch . Automatic width adjust. Full safety cover enclosure with ESD safe windows. "Left to Right" process flow, front fixed rail (standard). "Right to Left" process flow – front fixed rail (optional). ESD grounding receptacle (optional) & audible alarm. Roller wheels allowing for easy movement. Powder coated vanity panels, “PROMATION White" or "Light Gray”. Conforms to SMEMA spec. 1.2 / NFPA 79 Includes two standard SMEMA cables.

The VL-60 is a high capacity PCB line loader that can hold up to 160 PCBs. This vacuum lift system provides an intelligent pathway between machines via SMEMA interface and uses several PLC timers to track PCB progress and machine sequence. This fully enclosed system provides spacious, open access for PCB loading. Both "Load" and "Pass" modes are available. Individual ON~OFF values are used for each vacuum cup allowing for easy use for lifting small to large PCBs. A hand crank is used to adjust rail width. Roller wheels and leveling feet allow for quick integration into the line.

SIGNATURE FEATURES: Programmable Logic Controller. Single drive configuration (with rail separation). Transport speed (180mm/sec Fixed) – Variable speed optional. Dual E-Stops and master On / Off switch (Optional). Hand crank for width adjust. Automatic width adjustment (optional). Full safety cover enclosure with ESD safe windows. Roller wheels allowing for easy movement. "Left to Right" process flow, front fixed rail (standard). Right to left process flow – front fixed rail (optional). ESD grounding receptacle (Optional) & audible alarm. Powder coated vanity panels, “PROMATION White" or "Light Gray”. Conforms to SMEMA spec. 1.2 / NFPA 79 Includes two standard SMEMA cables. Independent vacuum cup control* (On~Off) PCB counter.

The LLD Series Magazine handler is a “Line Loading” solution that is used to populate the line with PCBs. This unit typically placed before a Screen Printer or Bare PCB line loading station, and provides an intelligent pathway between machines / processes via SMEMA interface and uses PLC timers to track PCB progress out of the magazine. The unit has automatic magazine change-over and adjustable pitch (10mm up to 50mm). Roller wheels and leveling feet allow for quick integration into the line. Front Load and Side magazine buffer available. Available Configurations: Single, Dual, four and five magazine in-line configurations, dual front load, dual and quad rear load

SIGNATURE Features: PLC Controller (Panasonic) Left to Right Process Flow, Front Fixed Rail Adjustable pusher position (manual) Adjustable flow control for pusher / PLC tracking Single Front Load/Unload magazine system E-Stop, On/Off Roller wheels and leveling feet Powder coated panels (PROMATION Off White) 10 foot power cord (detachable) One SMEMA cable Pass Line Height (950mm nominal +/- 30mm) Designed for 50 slot magazines (Nikko/Cab) 110V Power Outlet / 15A standard circuit Full safety covers (CE Type) PCB Top / Bottom side clearance 40 mm Touch Panel with Password Protection PW for adjusting pusher timer Select No of PCBs to be run from each magazine Select Pitch (10 ~ 50mm) in 10mm increments Full magazine notification Integrated conveyor with hand crank for width adjustment. Fixed belt speed

Our ULD magazine handler is a “line unloading” solution that is used to accept PCBs from the line and populate the magazine. This unit is typically placed at the end of the line and provides an intelligent pathway between machines / processes via SMEMA interface. The system uses PLC timers to track PCB progress into the integrated conveyor and magazine. The unit has automatic magazine change-over and selectable pitch (10mm up to 50mm). Roller wheels and leveling feet allow for quick integration into the line. Configurations: Single, Dual, four and five magazine in-line configurations, dual front load, dual and quad rear load

SIGNATURE Features: PLC Controller (Panasonic) Left to Right Process Flow, Front Fixed Rail Adjustable pusher position (manual) Adjustable flow control for pusher Single Magazine Solution Front loading / unloading E-Stop, On/Off Roller wheels and leveling feet Powder coated panels (PROMATION Off White) 10ft power cord (detachable) One SMEMA cable Pass Line Height (950 mm nominal +/- 30mm) Designed for 50 slot magazines (Nikko/Cab) 110V Power Outlet / 15A standard circuit Full safety covers (CE Type) PCB Top / Bottom side clearance 40 mm Touch Panel with Password Protection PW for adjusting pusher timer Select No of PCBs to be run from each magazine Select Pitch (10 ~ 50mm) in 10mm increments Full magazine notification Integrated conveyor with hand crank for width adjustment. Fixed belt speed

The WT Inspection conveyors are used to inspect PCBs or hand insert additional components prior to reflow or wave. PCBs are transported on 3mm ESD edge belts. This unit provides an intelligent pathway between machines / processes via SMEMA interface and uses PLC timers to track PCB progress. A hand crank is used to adjust rail width which folds neatly back into the panel so it never gets lost. Roller wheels and leveling feet allow for quick integration into any SMT line.

SIGNATURE FEATURES: ESD grounding receptacle (Optional) and Audible alarm. Overhead lighting with On / Off switch. Roller wheels allowing for easy movement. Powder coated vanity panels, "PROMATION White" or "Light Gray". Conforms to SMEMA spec. 1.2 / NFPA 79 Includes two standard SMEMA cables. Semi-circle or straight front work surface (optional). Adjustable rear parts tray (optional). Automatic width adjustment (optional). Jumper for non-SMEMA reflow (optional). Programmable Logic Controller. Single and multi-belt drive configurations available. Variable speed control. Check and Pass mode selector switch (foot pedal release). Dual E-Stops (Optional) and master On / Off switch. Retractable hand crank for width adjustment. Left to right process flow - front fixed rail (standard). Right to left process flow - front fixed rail (optional). Rear fixed rail options available*

CC Series conveyors are used to transport PCBs on 3mm ESD edge belts. This unit provides an intelligent pathway between machine processes via SMEMA interface and uses PLC timers to track PCB progress. A retractable hand crank is used to adjust rail width which folds neatly back into the panel so it never gets lost. Roller wheels and leveling feet allow for quick integration into the production line.

SIGNATURE FEATURES: Programmable Logic Controller. Top cover option with see through window. Single and multi-belt drive configurations available. Bar code reader can be attached (optional). Transport speed (180mm/sec Fixed) Variable speed control (optional) Thermal probe option releases PCB when a certain temperature has been met. Dual E-Stops (Optional)and master On / Off switch. Cooling fan options available. Retractable hand crank for width adjustment. Includes two standard SMEMA cables. Lengths: 500mm up to 3000mm. "Left to Right" process flow – front fixed rail (standard). "Right to Left" process flow – front fixed rail (optional). ESD grounding receptacle (Optional)& audible alarm. Roller wheels allowing for easy movement. Powder coated vanity panels, “PROMATION White" or "Light Gray”. Conforms to SMEMA spec. 1.2 / NFPA 79 Custom systems also available to meet any production need.

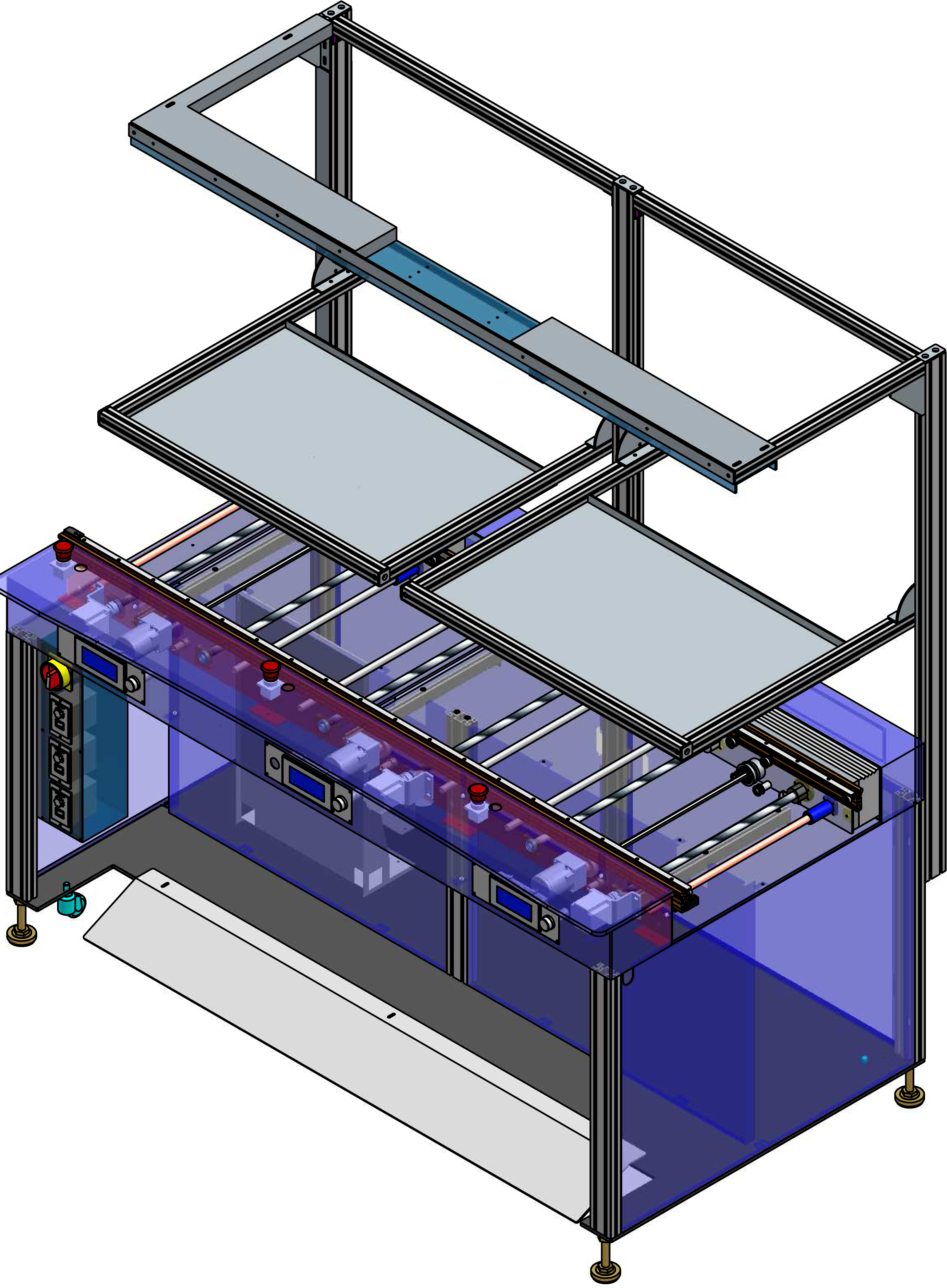

PROMATION offers a variety of line buffering solutions that are designed to assist with varying process speeds creating continuous line flow. PCBs can be stored in the vertical buffer and transferred to the next position in line when requested to do so. The VBB-10 Vertical Belt Buffer system has multiple configurations which are specified below.

SIGNATURE Features: PLC Controller (Panasonic) Left to Right Process Flow, Front Fixed Rail All belt type buffering solution – Magnetic Drive 3mm edge contact Precision indexing function 1 or 2 pitch select In feed conveyor side Automatic Width Adjustment E-Stop, On/Off, Light Tower Roller wheels and leveling feet Powder coated panels (PROMATION Off White) 10ft power cord (detachable) Pass Line Height (950mm nominal +/- 30mm) 72 PSI Air (5 Bars) 110V Power Outlet / 15A standard circuit Full safety covers PCB Top / Bottom side clearance depends on slot selection * PCB weight limit 1kg per PCB slot Options: Out feed conveyor side 10 slots @ 33mm spacing (pitch) 15 Slots @ 22mm spacing (pitch) 20 Slots @ 17mm spacing (pitch) Cooling Fans on Conveyor section 900mm nominal +/- 30mm Right to Left process flow 220V Power Outlet

PROMATION ‘s slide line work stations are great for hand placing components, mounting odd form components, inspecting solder and/or conducting rework. Our Signature frictionless steel roller chain allows product to glide effortlessly during the assembly/transfer process. Available in both power and non-power transfer, these work stations can be used to directly feed a reflow oven or wave.

SIGNATURE FEATURES: Programmable Logic Controller. Signature 06b frictionless steel roller chain. Bright overhead lighting with master On / Off switch. Adjustable rear parts tray. Retractable hand crank for width adjustment. Improved ergonomic design with low profile front for operator comfort / reach. “Left to right” process flow – front fixed rail (powered version). Bi-directional flow – front fixed rail (non-powered version). Operator ESD grounding ports & operator foot rests. Roller wheels allowing for easy movement. Powder coated vanity panels, “PROMATION White" or "Light gray” Conforms to SMEMA spec. 1.2 / NFPA 79

Product Handling Capability: Edge contact / clearance: 0.118” (3mm) 4.5mm overall PCB Length: 3” – 20” (75mm – 508mm) PCB Thickness: 0.5mm ~ 4.4mm PCB Width: 2” – 18” (50mm – 458mm) Above board clearance: 1.50” (40mm) Below board clearance: 1.50” (40mm) Available Lengths: 1 operator / 1 meter

Options Include: “Go PRO” LCD Touch Panel Interface with Automatic Width Adjust. LCD Instructional Display Articulating Arm Mounts. Variable Speed (Powered Version). Additional parts storage (Articulating Arm with Bin Panel). Document holders.

PROMATION offers two type of wave loaders. The WIC-60 is an angled conveyor that feeds the wave and the DTF-80 is an automatic wave loading system that accepts PCBs from an edge rail. The loading system then drops, tilts, and feeds the wave fingers. The standard version uses 3mm ESD edge belts to transfer PCBs. Our HD Series is for pallet transfer and uses our heavy duty ESD timing belts. Pallets are still transferred on 3mm edge however the HD belts have a greater durability for heavier weighted pallets.

SIGNATURE FEATURES: “Left to Right” process flow – front fixed rail (standard). "Right to Left" process flow (optional). ESD grounding receptacle & audible alarm. Roller wheels allowing for easy movement. Powder coated vanity panels, “PROMATION White" or "Light Gray”. Conforms to SMEMA spec. 1.2 / NFPA 79 Includes two standard SMEMA cables. Programmable Logic Controller. Customer must provide wave entrance height & angle details* Single drive configuration (standard edge or timing belt). Variable speed control. Dual E-Stops and master On / Off switch. Auto Wave Loader offers motorized carriage movement (up and down)(angle).

Our wave unloading solutions accept PCBs from the wave (on edge rail) at an incline angle and then re-angles the PCB to a decline conveyor or elevator system to return the PCB back to SMEMA height. The standard version uses 3mm ESD edge belts to transfer PCBs. Our HD series is for pallet transfer and uses our heavy duty ESD timing belts or pin chain solution. Pallets are still transferred on 3mm edge but chain or timing belt conveyance solutions may offer a greater durability for heavier weighted pallets.

SIGNATURE FEATURES: "Left to Right process flow – front fixed rail (standard). "Right to Left" process flow (optional). ESD grounding receptacle & audible alarm. Industrial roller wheels allowing for easy movement. Powder coated vanity panels, “PROMATION White" or "Light Gray”. Conforms to SMEMA spec. 1.2 / NFPA 79 Includes standard SMEMA out (if required). Incline / decline conveyor set. Programmable Logic Controller. Dual drive configuration (standard edge or timing belt) (ESD Flat Belt also available). Customer must provide wave exit height and angle details* Variable speed control. Retractable hand crank for width adjustment. Dual E-Stops and master On / Off switch. Top side cooling fan banks optional (over incline section).

Our CWT Series turn stations may be used to transfer PCBs around a corner for continuous flow in production or the JTS-50 can sort Good and NG PCBs after AOI. “Good” PCBs pass through and "NG" PCBs are re-routed to the front or rear of the line. Junction type turns are also available. Each system provides an intelligent pathway between machines / processes via SMEMA interface and uses PLC timers to track PCB progress. Systems are built for CW, CCW, Junction, and pass/fail sort configurations. A hand crank is used to adjust rail width. Roller wheels and leveling feet allow for quick integration into the line.

SIGNATURE FEATURES: Programmable Logic Controller. "Sorting" SMEMA for Post AOI and Junction configurations available (optional). Single drive configuration (shuttle and turn movement). Transport speed (180mm/sec) fixed. Dual E-Stops (Optional)and master On / Off switch. Retractable hand crank for width adjustment. Clock-wise, counter clock-wise, and sort configurations available. Conforms to SMEMA spec. 1.2 / NFPA 79 “Left to right” process flow – front fixed rail (standard). “Right to left” process flow – front fixed rail (optional). ESD grounding receptacle (Optional)& audible alarm. Roller wheels allowing for easy movement and rubber bottom leveling feet. Powder coated vanity panels, “PROMATION White" or "Light Gray” . Includes two standard SMEMA cables. Automatic Width control (optional).

PROMATION ‘s FC-50 flip stations are offered for standard flipping of PCBs during two sided production and bi-directional process flow when two sided marking or coating is required. These systems use dual inverted 3mm ESD edge rails to secure product during the flip cycle. This unit provides an intelligent pathway between machines / processes via SMEMA interface and uses PLC timers to track PCB progress. The bi-directional system can use either manual selection or fully integrated SMEMA for automatic control over the hand back sequence. A hand crank is used to adjust rail width. Roller wheels and leveling feet allow for quick integration into the line.

SIGNATURE FEATURES: Left to right process flow – front fixed rail (standard). Right to left process flow – front fixed rail (optional). ESD grounding receptacle & audible alarm. Roller wheels allowing for easy movement. Powder coated vanity panels, “PROMATION White" or "Light Gray”. Conforms to SMEMA spec. 1.2 / NFPA 79 Includes two standard SMEMA cables. Bi-directional control (optional). Programmable Logic Controller. LCD touch panel interface (optional). Automatic width control (optional). Single drive configuration (with inverted rail sets). Fixed belt speed (180mm/sec) – variable speed (optional). Dual E-Stops and master On / Off switch. Hand crank for width adjust.

PROMATION's CC-06b and CC-PC conveyors utilize either Steel 06b Roller Chain Belts or Pin Belts to transport PCBs. These conveyors may be programmed for continuous running, progressive indexing, or standard point to point transfer. The retractable hand crank is used to adjust rail width which folds neatly back into the panel so it never gets lost. Variable speed control is standard on this model. Roller wheels and leveling feet allow for quick integration into the production line.

SIGNATURE FEATURES: ESD grounding receptacle (Optional)and audible alarm. Roller wheels allowing for easy movement. Powder coated vanity panels, "PROMATION White" or "Light Gray". Conforms to SMEMA spec. 1.2 / NFPA 79 Includes two standard SMEMA cables. Top cover option available. Bar code reader (s) (optional). Full alert and light tower (3 color) (optional) Cooling fan (optional). Programmable Logic Controller. Single drive configuration (multi-stop locations also available). Variable speed control. Dual E-Stops (Optional)and master On / Off switch. Retractable hand crank for width adjustment. Automatic width adjustment (optional). Left to right process flow - front fixed rail (optional). Right to left process flow - front fixed rail (optional). Rear fixed rail options available.

Our CGC-80C and TGC-80 series passageway conveyors are used to provide an open pathway through the production line. The conveyor shuttle “extends to deliver” PCBs across the pathway. PCBs are transported on 3mm ESD edge belts. These units provide an intelligent pathway between machines / processes via SMEMA interface and uses PLC timers to track PCB progress. A hand crank is used to adjust rail width. The servo drive allows users to set the perfect extension speed as well as program the distance the conveyor shuttle travels. The maximum standard opening is 800mm but other custom lengths can also be built. Roller wheels and leveling feet allow for quick integration into the line.

SIGNATURE FEATURES: Programmable Logic Controller. Servo drive for programmable extension distance, extension speed and retraction speed. (800 mm or 900 mm openings) . LCD touch panel Interface. Dual E-Stops (Optional)and master On / Off switch. Retractable hand crank for width adjustment. . Automatic width adjustment (optional). Left to right process flow – front fixed rail (standard). Right to left process flow – front fixed rail (optional). Look across safety sensing (3 locations). Accidental Bump Bar with Auto Retraction. ESD grounding receptacle (Optional)& audible alarm. Roller wheels allowing for easy movement. Powder coated vanity panels, “PROMATION White" or "Light Gray”. Conforms to SMEMA spec. 1.2 / NFPA 79 Includes two standard SMEMA cables.

For high output production or line balancing through reflow, PROMATION offers a complete line of dual lane handling systems. Systems Include: - Slide Shuttles (Combiners / Separators) - Transfer Conveyors - Work Stations - Magazine Handlers - and much more.

SIGNATURE FEATURES: Programmable Logic Controller. LCD touch panel interface(optional). Single drive and multi-belt drive configurations available. Fixed belt speed (180mm/sec) – variable speed optional Dual E-Stops (Optional)and master On / Off switch. Hand crank for width adjust. (automatic width adjust optional). Top-side safety cover enclosures available. Left to right process flow – front fixed rail (standard). Right to left process flow – front fixed rail (optional). ESD grounding receptacle (Optional) & audible alarm. Roller wheels allow for easy movement. Powder coated vanity panels, “PROMATION White" or "Light Gray”. Conforms to SMEMA spec. 1.2 / NFPA 79 Includes two, three, or four standard SMEMA cables.

Our NRC Series sorting conveyors are used for inspection of PCBs after SPI inspection. In check mode, the system receives a PASS / NG signals from the SPI machine after each inspection. If a No Good signal (Fail) is received via SMEMA, the PCB stops in front of the operator and the finger set lifts the failed PCB for inspection while allowing good PCBs to continue to pass underneath. When the inspection is complete, the operator may leave the PCB in place or remove it by hand. When the foot pedal is depressed the finger set returns to its home position. If a PCB is present, SMEMA is enabled to continue transfer; If no PCB is detected the conveyor re-sets. In pass mode, the station acts as a normal conveyor, providing end to end transfer.

SIGNATURE FEATURES: PLC Controlled Touch Panel User Interface Automatic Width Adjustment Sorting SMEMA Safety Curtain Sort and Pass mode selection AVAILABLE OPTIONS: Conveyor speed control Monitor / Keyboard mount Front work surface RS-485 Communication 900mm nominal pass line LED Status Light Tower

NOTE: The PCB in fail mode is lifted over the top of the edge belt. Actual clearance is dependent upon top side height of components passing underneath the lifted PCB and if there are any bottom side components on the lifted PCB. Please look at these calculations to determine if this station is proper for the application.*

Our MFMH Series of Magazine Sorting Systems have been specifically designed for post AOI sorting of PCBs in a batch process mode. This in-line solution sorts PCBs according to Pass or Fail status. The system passes good PCBs through the magazine and stores suspect PCBs in a magazine. Slot spacing is selectable in 10mm increments. Once the magazine is full, the station alarms, notifying the operator that the magazine needs to be replaced. With the platform lowered, the magazine/platform shuttles forward making magazine removal effortless.

SIGNATURE Features: PLC controlled Touch Panel User Interface Select No of PCBs and Pitch SMEMA 10 ~ 50mm pitch selection Front Loading Solution Automatic Magazine Change-over LED Status Light Tower Safety Covers 50 slot magazines @ 10mm pitch Available options: Electric type pusher Automatic pusher alignment PCB Exit guide (manual or motorized) RS-485 Communication 900mm nominal pass line

Our VBB Series of Multi-Functional buffer systems accept PASS & NG signals from the AOI System via SMEMA interface and sorts incoming PCBs accordingly. The system uses a 12 slot vertical buffer for suspect PCBs, while utilizing a lower pass-through conveyor (lower level) for GOOD PCBs. Suspect PCBs are carried to an upper conveyor level for Review/Rework and can effortlessly be reintroduced into the production line should the suspect PCB be a “false failure”. Select No of PCBs to prohibit transfer into reflow from previous conveyor. (Note: requires Long SMEMA cable option).

SIGNATURE Features: PLC Controller (Panasonic) Left to Right Process Flow, Front Fixed Rail All belt type buffering solution – Magnetic Drive 3mm edge contact Precision indexing function 1 or 2 pitch select In feed conveyor side Automatic Width Adjustment E-Stop, On/Off, Light Tower Roller wheels and leveling feet Powder coated panels (PROMATION Off White) 10ft power cord (detachable) Two SMEMA cables Pass Line Height (950mm nominal +/- 30mm) 72PSI Air (5 Bars) 110V Power Outlet / 15A standard circuit Full safety covers PCB Top / Bottom side clearance depends on slot selection * PCB weight limit 1kg per PCB slot Touch Panel LIFO / FIFO / PASS functions / Available Options: Out feed conveyor side 10 slots @ 35mm spacing (pitch) 15 Slots @ 22mm spacing (pitch) 20 Slots @ 17mm spacing (pitch) Cooling Fans on Conveyor section 900 mm nominal +/- 30mm Right to Left process flow 220V Power Outlet Select Number of PCBs to prohibit transfer into reflow from previous conveyor. (Note: requires Long SMEMA cable option)

The ASC-100TB is a fully programmable Top and Bottom Side Bar Code Scanning conveyor system. Using our standard Micro-scan barcode readers, the top and bottom side gantries can quickly be programmed to move to various locations on the PCB to read and verify bar codes (labels or laser marks).

standard features: PLC Controller (Panasonic) / Touch Panel Interface Left to Right Process Flow, Front Fixed Rail Cognex Code Readers (standard) Precision movement of readers based upon programming. Top and Bottom sides. Automatic Width Adjustment E-Stop, On/Off, Status Light Tower Roller wheels and rubber bottom leveling feet Powder coated vanity panels EX8816S-SR-WH020KCC Off White 10 foot power cord (detachable) SMEMA cables / Ethernet Cables Pass Line Height (950 mm nominal +/- 30mm) 72 PSI Air (5 Bars) 110V Power Outlet / 15A standard circuit PCB Handling capabilities: (x size unit) PCB Width Capability 75 mm x 458 mm PCB Length Capability 75 mm x 508 mm PCB Thickness 0.5 mm ~ 3.5 mm PCB Warpage Allowance +/- 0.05 mm Top Side PCB Clearance / Pass mode 25 mm Bottom Side PCB Clearance / Pass mode 40 mm Width Adjustment Automatic

The ASC-100TB is a fully programmable Top and Bottom Side Bar Code Scanning conveyor system. Using our standard Micro-scan barcode readers, the top and bottom side gantries can quickly be programmed to move to various locations on the PCB to read and verify bar codes (labels or laser marks).

standard features: PLC Controller (Panasonic) / Touch Panel Interface Left to Right Process Flow, Front Fixed Rail Cognex Code Readers (standard) Precision movement of readers based upon programming. Top and Bottom sides. Automatic Width Adjustment E-Stop, On/Off, Status Light Tower Roller wheels and rubber bottom leveling feet Powder coated vanity panels EX8816S-SR-WH020KCC Off White 10 foot power cord (detachable) SMEMA cables / Ethernet Cables Pass Line Height (950 mm nominal +/- 30mm) 72 PSI Air (5 Bars) 110V Power Outlet / 15A standard circuit PCB Handling capabilities: (x size unit) PCB Width Capability 75 mm x 458 mm PCB Length Capability 75 mm x 508 mm PCB Thickness 0.5 mm ~ 3.5 mm PCB Warpage Allowance +/- 0.05 mm Top Side PCB Clearance / Pass mode 25 mm Bottom Side PCB Clearance / Pass mode 40 mm Width Adjustment Automatic

PROMATION offers a complete PCB Handling line for large and Heavy Circuit Boards; Perfect for LED Manufacturing! Our HD Signature Series Models utilize a Heavy Duty ESD Timing Belt to transport PCBs along a 3mm edge contact for smooth and uninterupted Production Line Flow. Conveying Solutions include: 24", 36" and 48" long PCB Handling Systems. Call us to discuss your application in detail!

standard features: PLC Controller (Panasonic) / Touch Panel Interface Left to Right Process Flow, Front Fixed Rail Cognex Code Readers (standard) Precision movement of readers based upon programming. Top and Bottom sides. Automatic Width Adjustment E-Stop, On/Off, Status Light Tower Roller wheels and rubber bottom leveling feet Powder coated vanity panels EX8816S-SR-WH020KCC Off White 10 foot power cord (detachable) SMEMA cables / Ethernet Cables Pass Line Height (950 mm nominal +/- 30mm) 72 PSI Air (5 Bars) 110V Power Outlet / 15A standard circuit PCB Handling capabilities: (x size unit) PCB Width Capability 75 mm x 458 mm PCB Length Capability 75 mm x 508 mm PCB Thickness 0.5 mm ~ 3.5 mm PCB Warpage Allowance +/- 0.05 mm Top Side PCB Clearance / Pass mode 25 mm Bottom Side PCB Clearance / Pass mode 40 mm Width Adjustment Automatic

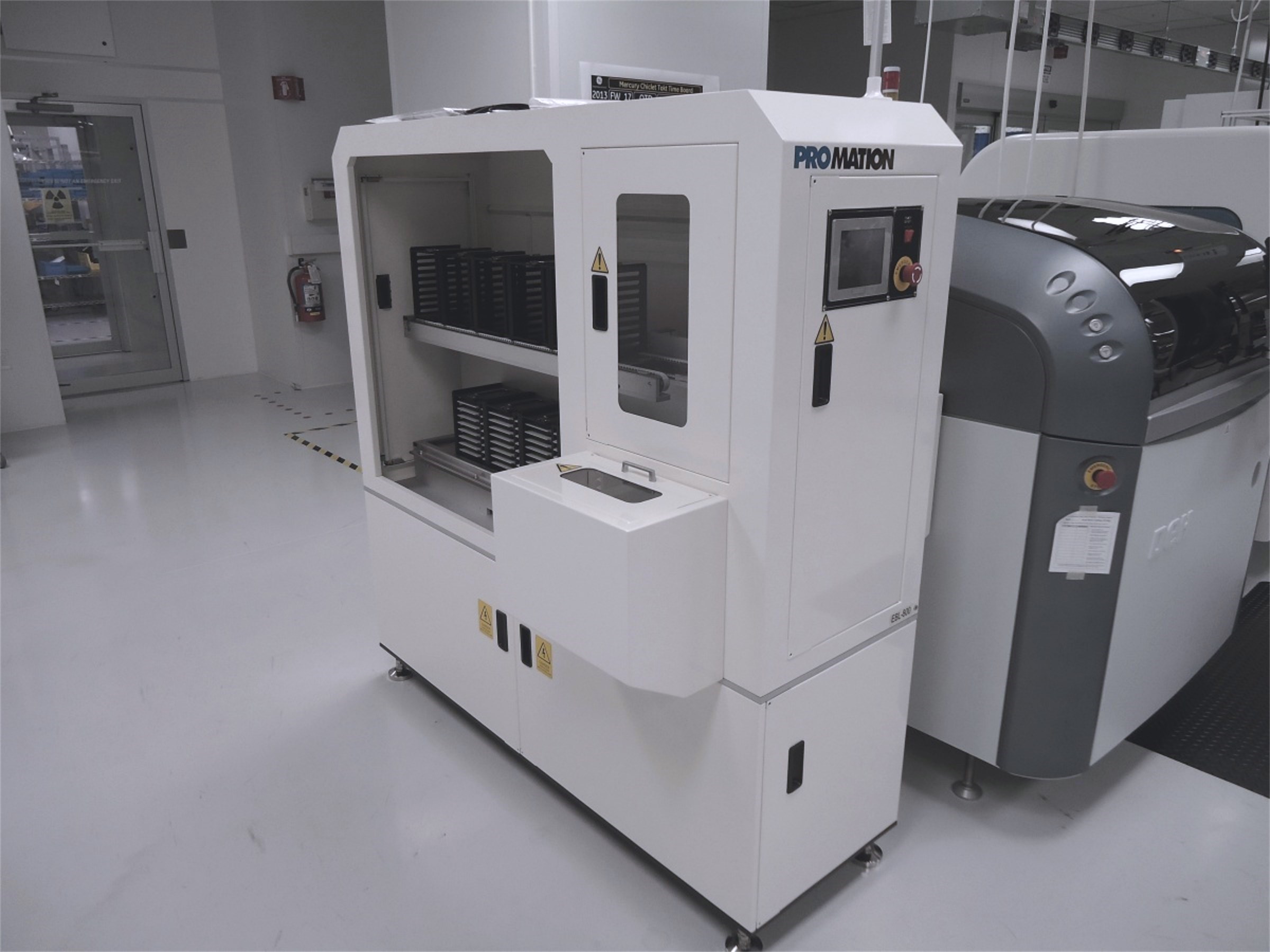

EBL-800 (loader) ebu-800(unloader): Our EBL and EBU systems have been designed to operate in a Class 100K clean rooms and provide reliable handling to either substrates or ceramic type products. The Line Loader handles products from an aluminum carrier (Auer/ Precision / Others) than transfers the product to the next station. The Line Unloader is designed to accept product (from the line) and return the product to the carrier for safe storage. Optional carrier orientation validation and bar code readers are available.

SIGNATURE FEATURES: Programmable Logic Controller. High capacity carrier rack. LCD touch panel interface. Capable of handling up to 5 aluminum magazines top / bottom. Operator controls: E-Stop, Reset, Touch Panel. Left to right process flow. Front fixed rail. Audible alarm and 3 color light tower. Angled buffer section minimizes floor space requirements. Automatic magazine change over. Optional bar code readers. Optional carrier orientation verification. Includes standard 14-pin communication cable (4 pin configuration). Powder coated vanity panels, "PROMATION White" or "Light Gray". Conforms to SMEMA Spec. 1.2 / NFPA 79 Automatic

by 700+ customers for 3200+ clients