What are the advantages?

Return on Investment - PROMATION offers the best value in Robotic Soldering. Customers often see a ONE YEAR Return on Investment!

Less Rework - Once the soldering program is set to the user's desired quality level, the robot will perform its function the exact same way, every single time. By eliminating human error, users can expect far less defects, resulting in less rework, and more throughput.

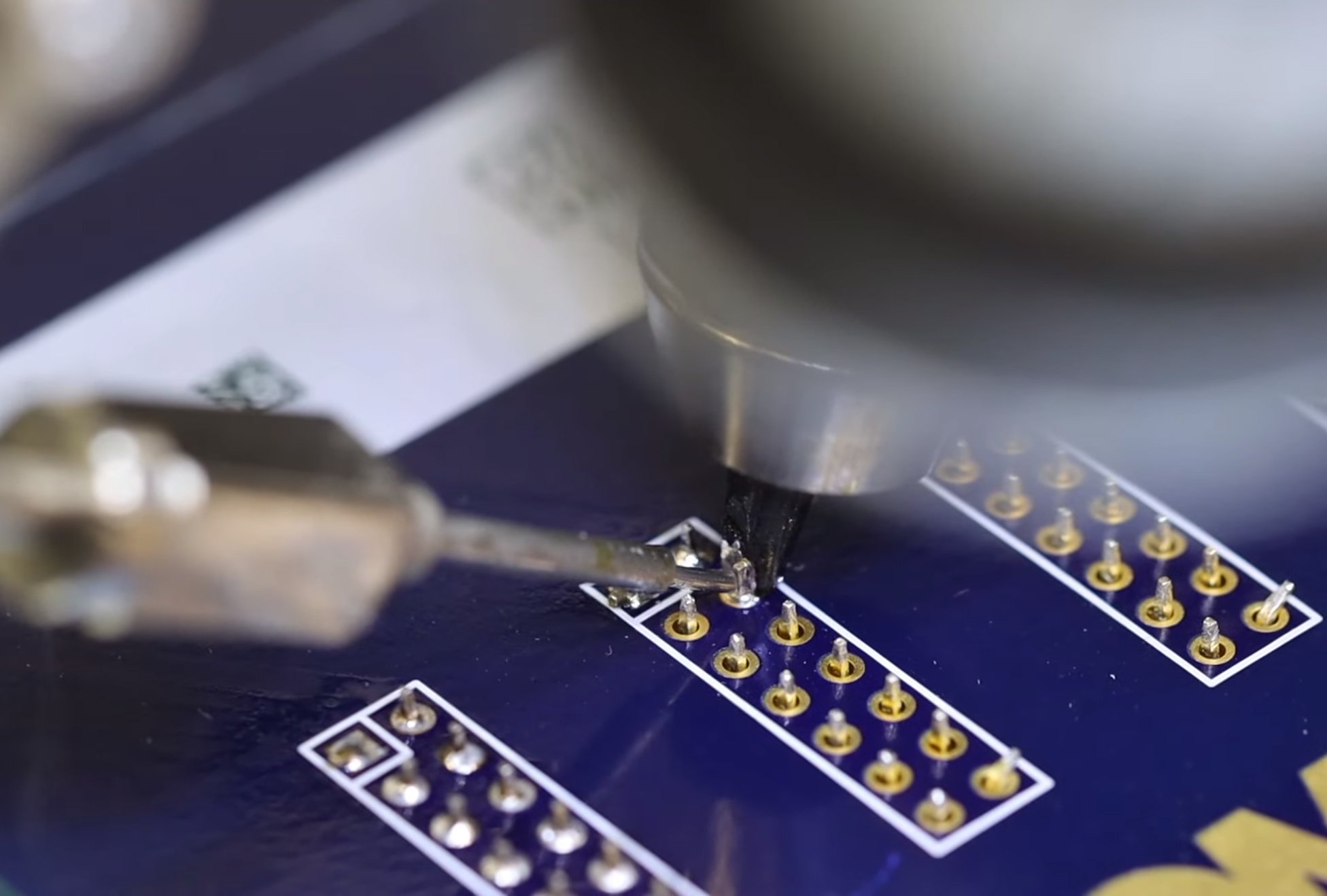

Highly Efficient - Robotic work stations require a minimal amount of operator involvement after they have been installed and programmed. In most production settings, one operator can be responsible for loading, supervising, and unloading two robots. One trained soldering expert can program multiple machines, thus, eliminating the cost of advanced training for each hand soldering operator. We also offer a Dual-Tip Soldering Robot capable of soldering two joints at once.

Versatility - Virtually no job is too large, or too small. Our systems are capable of HMP and Lead-free soldering. Options include but are not limited to: Nitrogen Sleeves, Vision Guidance, and Safety Enclosures. There is also a wide range of Hot Iron Tip sizes and shapes. Custom fixtures for any application are available!

PROMATION USA offers the largest variety of soldering robot models in the world. While this is just a sample of our offering, please contact your Authorized PROMATION USA Representative if you require a specific working area or technology so we may custom tailor the solution to meet your production / automation objectives.

DOWNLOAD THE BROCHURE

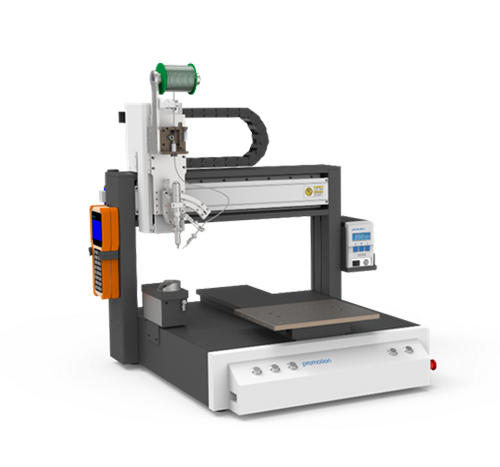

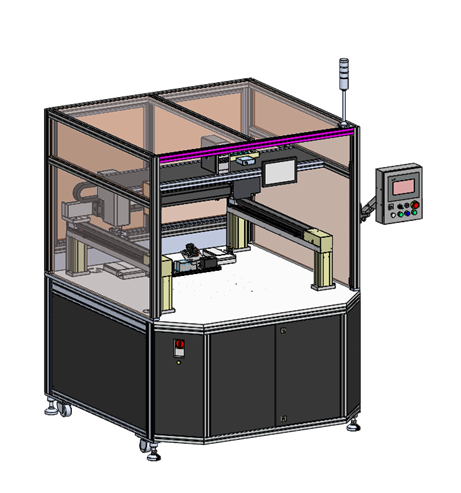

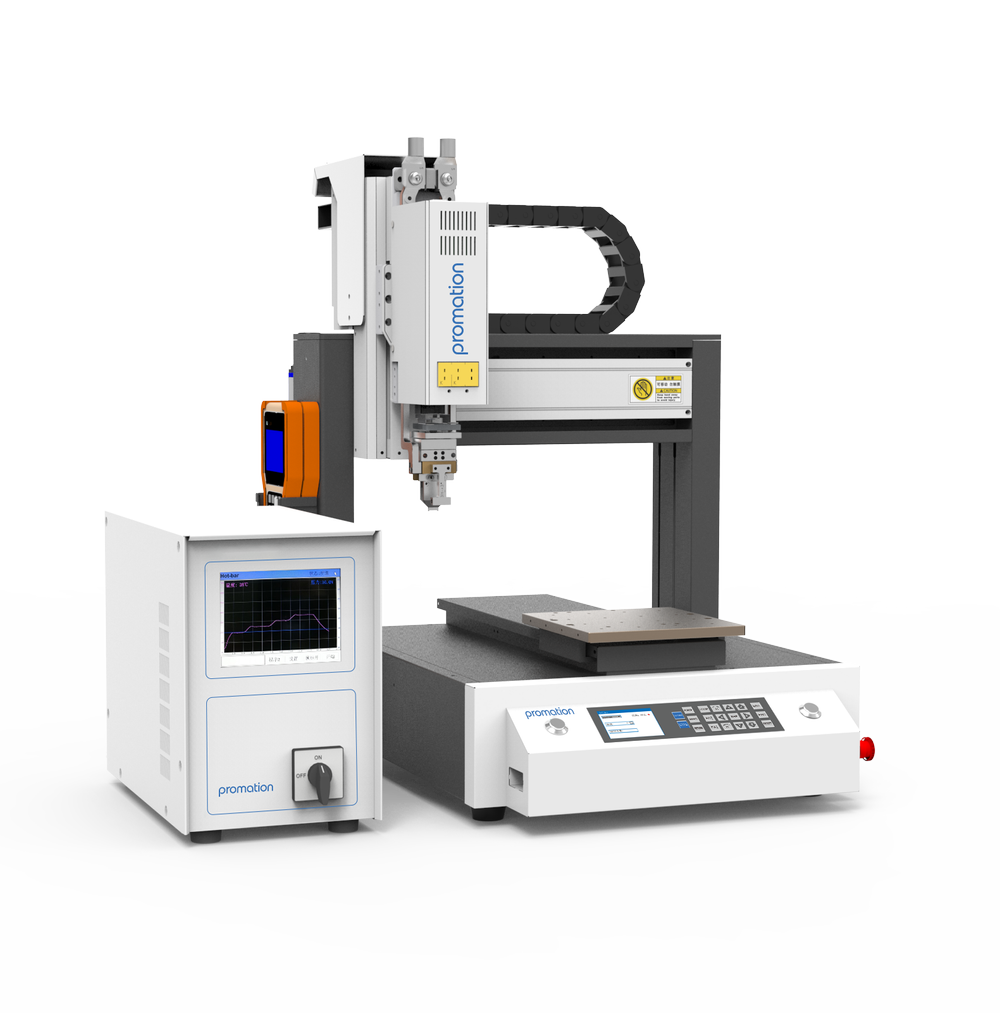

Fixed Configuration Soldering Robots offering an entry level price point. Standard Features: Industrial Grade 150 Watt Soldering Iron. Precision Solder Feeding Station. Integrated Solder Tip Cleaning Station. Compact Machine Footprint. Easy-to-use “Point and Teach” Programming Method

Introducing The E SERIES: Our Signature Collection of Soldering Robots.

Standard Features: 180 Watt High Performance Soldering Technology Signature HD Process Viewing Camera Kit On-Board Nitrogen Generator w/ Heated N2 Output Kit High Efficiency Solder Tip Cleaning Station End-Effector Fume Extraction High Precision Solder Feeding Station and more…. SAFETY ENCLOSURES: Floor Standing ESC40AC w/ Integrated Keyence Light Curtain Purposefully Designed and Built Custom Enclosures. Optional Upgrades: Integrated HMI Touchscreens (Cobot Ready) Upgraded Solder Tip Cleaning Stations Multi-Head Configuration Dynamic Vision Alignment Kit w/ PC Solder Wire Preheat Kit Solder Tip Correction

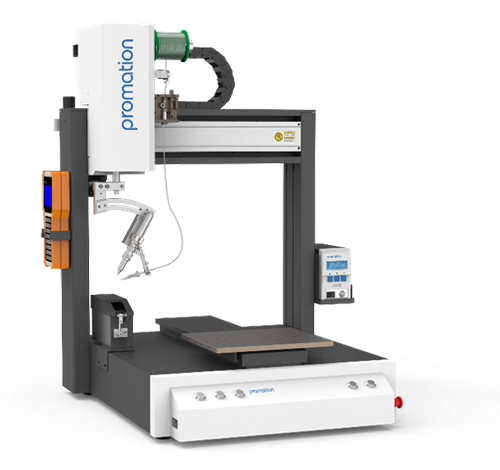

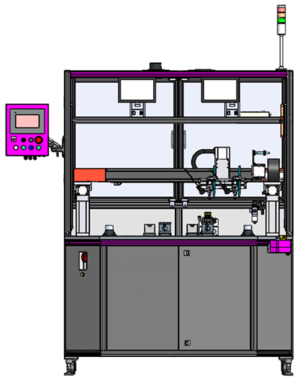

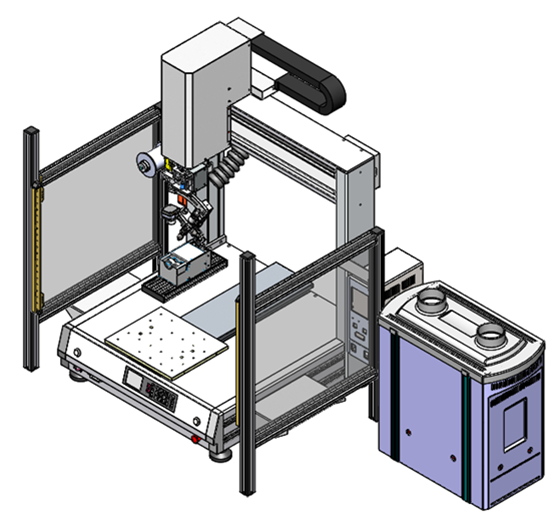

N SERIES SOLDERING. Flexible Soldering Platforms Designed for A Variety of Applications.

Standard Features: 150 ~ 320 Watt High Performance Soldering Technology Signature HD Process Viewing Camera Kit Performance Solder Tip Cleaning Station End-Effector Fume Extraction High Precision Solder Feeding Station and more…. SAFETY ENCLOSURES: Floor Standing ESC40AC w/ Integrated Keyence Light Curtain Purposefully Designed and Built Custom Enclosures. Optional Upgrades: Integrated HMI Touchscreens (Cobot Ready) On-Board Nitrogen Generator w/ Heated N2 Output Kit Upgraded Solder Tip Cleaning Stations Multi-Head Configuration Dynamic Vision Alignment Kit w/ PC Solder Wire Preheat Kit Solder Tip Correction

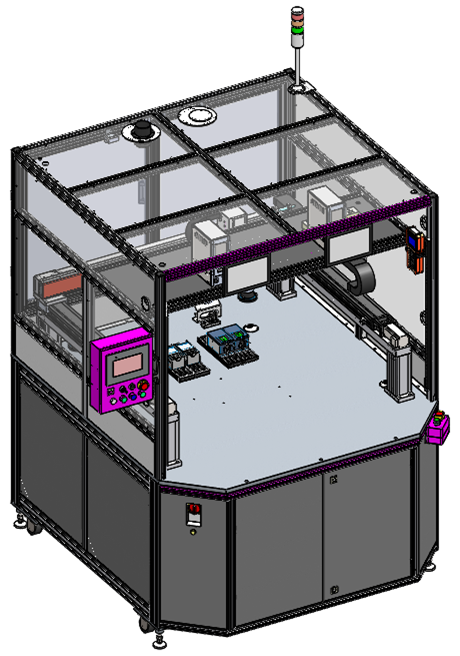

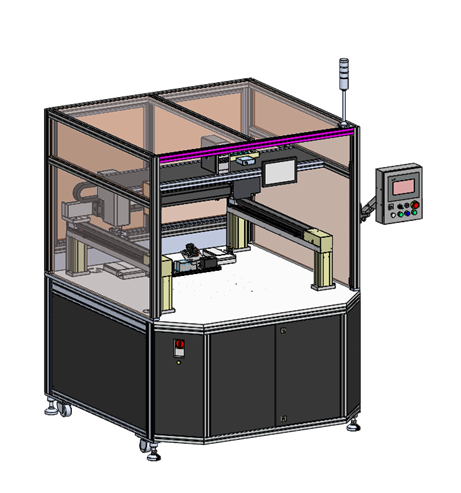

F SERIES SOLDERING. Beautifully Crafted. Feature Rich. Premium Soldering Technology.

Standard Features: Dynamic Vision Alignment w/ Model Matching On-Board Nitrogen Generator w/ Heated N2 Output Kit 180 Watt High Performance Soldering Technology Signature HD Process Viewing Camera Kit Solder Tip Correction Dual Solder Tip Cleaning Stations End-Effector Fume Extraction Integrated HMI Touchscreens (Cobot Ready) Ultra High Precision Solder Feeding Station and more…. SAFETY ENCLOSURES: Floor Standing ESC40AC w/ Integrated Keyence Light Curtain Table-Top Tempered Glass Enclosure w/ Integrated Keyence Light Curtain Purposefully Designed and Built Custom Enclosures.

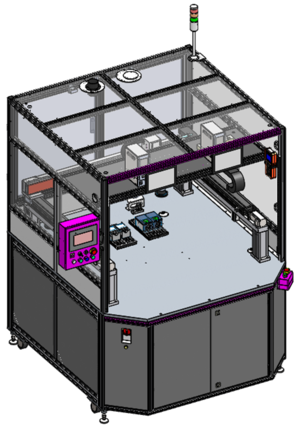

M SERIES SOLDERING. Beautifully Crafted. Feature Rich. Premium Soldering Technology.

Standard Features: Dynamic Vision Alignment w/ Model Matching On-Board Nitrogen Generator w/ Heated N2 Output Kit 180 Watt High Performance Soldering Technology Signature HD Process Viewing Camera Kit Solder Tip Correction Dual Solder Tip Cleaning Stations End-Effector Fume Extraction Integrated HMI Touchscreens (Cobot Ready) Ultra High Precision Solder Feeding Station and more…. SAFETY ENCLOSURES: Floor Standing ESC40AC w/ Integrated Keyence Light Curtain Table-Top Tempered Glass Enclosure w/ Integrated Keyence Light Curtain Purposefully Designed and Built Custom Enclosures.

.jpg)

.jpg)

The 9N393W Series of Hot Air Soldering Robots feature a robust heating system with a variety of heat focusing nozzles. The system generates a Heated Vortex of Nitrogen to create a localized convectional heat; allowing for localized reflow of solder paste in fine pitch and tight-to-reach applications. The heating system is capable of delivering and maintaining a set temperature with industry leading stability and accuracy. With solder paste applied to the soldering targets, the robot is intended to move to pre-programmed locations and apply a set amount of heat for a set amount of time.

All systems come standard with a 300W Power Supply capable of maintaining a temperature of up to 500°C, A variety of nozzles, color CCD "Witness Cameras" and light screen safety enclosures are optional.

.png)

The 9R393T Series of Molten Drop Soldering Robots feature a robust heating system with a variety of nozzles. The heating system is capable of delivering and maintaining a set temperature with industry leading stability and accuracy. Solder wire is fed and cut based on a variable setting. After being fed and cut, the wire is made molten by the heat source and applied directly to the joint through the nozzle.

All systems come standard with a 300W Power Supply capable of maintaining a temperature of up to 500°C, A variety of nozzles, color CCD "Witness Cameras" and light screen safety enclosures are optional.

Features: Robust heating capability with stable temperature. Wide variety of tips / nozzles. Patented constant wire feed system designed for stable and precise feeding. Slim profile iron for soldering in hard to reach locations. Greatly reduces solder splatter and solder ball defects.

System specifications: SOLDER WIRE DIAMETER RANGE: 0.6mm - 1.2mm WIRE CUTTING LENGTH RANGE: 0.4mm - 1.7mm (up to 4 portions per application) TEMPERATURE RANGE: 50°C-500°C HEATING POWER: 300W SOLDERING IRON TYPE: 9019

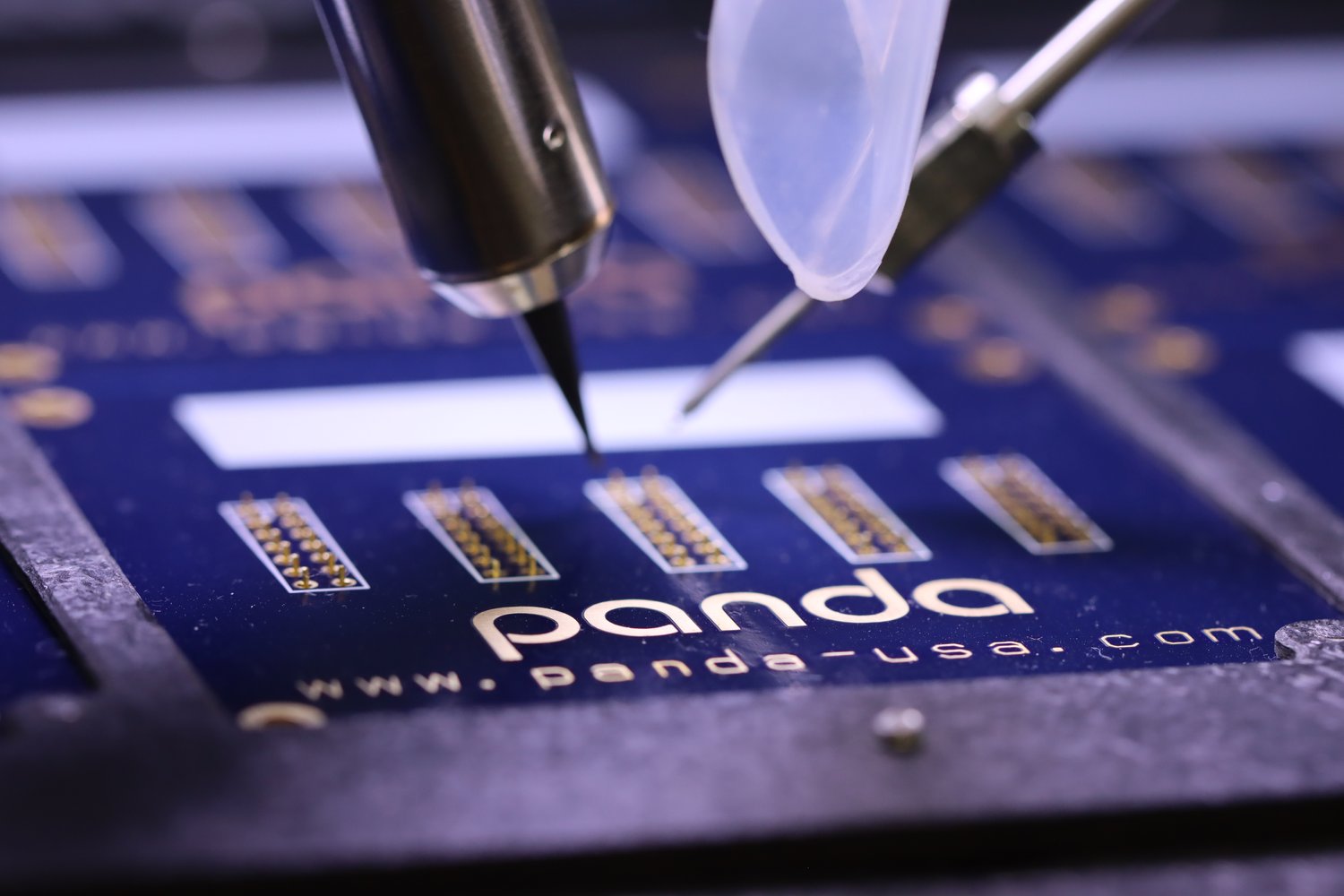

the Ultimate soldering solution for Contract Mfg: The 9544CJ PRO Model Series features a robust Hot Iron soldering system with a superior closed loop temperature sensor. The Hot Iron is capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. Two fine-toothed gears work to pull Solder from the Solder Spool while also perforating the surface of the Solder Wire to allow for better out gassing of the Flux Core.

Better out gassing of the flux core results in less solder ball and flux splatter defects. All systems come standard with a 180W Power Supply capable of maintaining a temperature of up to 420°C, automatic solder feeder, dual tip cleaning stations, and positive tip location. Nitrogen blanket sleeves, Color CCD "Witness Cameras" and different style safety enclosures are also available.

Standard Features: Floor Standing Safety Enclosure / Work Cell Heated N2 Soldering Kit (Ideal for Lead-Free Applications) Upgraded Solder Tip Cleaning Stations (Non-Contact Compressed Air/N2 and Contact Dual-Rotating Brass Brush) HD Process Viewing Camera Kit Table-Top N2 Generator 9036 Solder Tip Correction Device Localized Fume Extraction at the Solder Tip

The Ultimate soldering solution for Contract Mfg.: The 9744CJ PRO Model Series features a robust Hot Iron soldering system with a superior closed loop temperature sensor. The Hot Iron is capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. Two fine-toothed gears work to pull Solder from the Solder Spool while also perforating the surface of the Solder Wire to allow for better out gassing of the Flux Core.

Better out gassing of the flux core results in less solder ball and flux splatter defects. All systems come standard with a 180W Power Supply capable of maintaining a temperature of up to 420°C, automatic solder feeder, dual tip cleaning stations, and positive tip location. Nitrogen blanket sleeves, Color CCD "Witness Cameras" and different style safety enclosures are also available.

Standard Features: Floor Standing Safety Enclosure / Work Cell Heated N2 Soldering Kit (Ideal for Lead-Free Applications) Upgraded Solder Tip Cleaning Stations (Non-Contact Compressed Air/N2 and Contact Dual-Rotating Brass Brush) HD Process Viewing Camera Kit Table-Top N2 Generator 9036 Solder Tip Correction Device Localized Fume Extraction at the Solder Tip

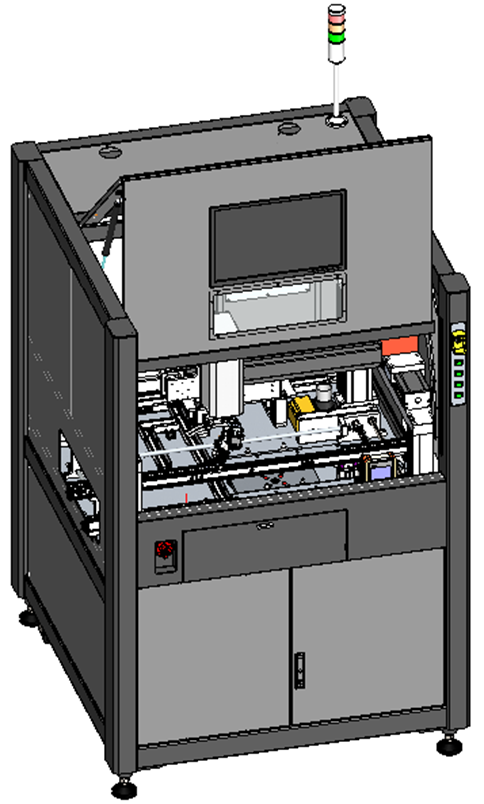

HIGH VOLUME PRODUCTION SOLDERING CELL: The 9433D PRO MODEL Series features a robust Hot Iron soldering system with a superior closed loop temperature sensor. The Dual Hot Irons are capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. High Accuracy Solder Feeding Stations work to pull Solder from the Solder Spool to allow for true volumetric indexing of material through the work cell.

All systems come standard with a 180W Power Supply capable of maintaining a temperature of up to 420°C, automatic solder feeders, dual tip cleaning stations, and positive tip location. Nitrogen blanket sleeves, Color CCD "Witness Cameras" and different style safety enclosures are also available.

Standard Features: Floor Standing Safety Enclosure / Work Cell Heated N2 Soldering Kit (Ideal for Lead-Free Applications) Upgraded Solder Tip Cleaning Stations (Non-Contact Compressed Air/N2 and Contact Dual-Rotating Brass Brush) HD Process Viewing Camera Kit Table-Top N2 Generator 9036 Solder Tip Correction Device Localized Fume Extraction at the Solder Tip

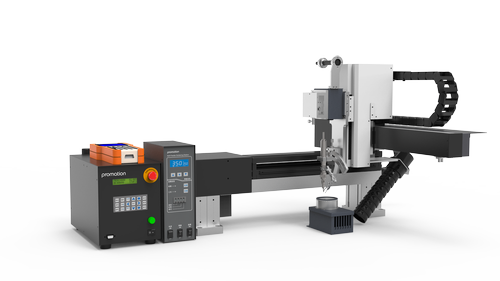

S100-T4 In-LINE Soldering Robot: The S100-T4 In-Line Soldering Machine features a robust Hot Iron system with a superior closed loop temperature sensor capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. Complete with a 150W Power Supply, a Wire Perforating Solder Feeder, 4-Axis Motion, Automatic Width Conveyor Bed, Adjustable End Effector, and a Tip Cleaning Station this system is more than capable of handling most any Soldering Application.

S100-T4 In-Line Soldering MACHINE OfferS New Technology: The S100-T4 has been redesigned to offer users the latest in soldering technology. The new upgraded unit is compatible with the following new technologies: Bottom-Side Pallet Return System Upgraded Solder Feed Station (for applications that require a higher degree of rotation) New Elegant Exterior Color Scheme New Quieter Operation

The S100-P4 In-Line Soldering Machine features a robust Hot Iron system with a superior closed loop temperature sensor capable of delivering and maintaining a tip temperature with industry leading stability and accuracy. Complete with a 150W Power Supply, a Wire Perforating Solder Feeder, 4-Axis Motion, Automatic Width Conveyor Bed, Adjustable End Effector, and a Tip Cleaning Station this system is more than capable of handling most any Soldering Application.

S100-P4 In-Line Soldering MACHINE OfferS New Technology: The S100-P4 has been redesigned to offer users the latest in soldering technology. The new upgraded unit is compatible with the following new technologies: Bottom-Side Pallet Return System Upgraded Solder Feed Station (for applications that require a higher degree of rotation) New Elegant Exterior Color Scheme New Quieter Operation

We offer Ultra-High Performance Hot Bar Soldering Robots. The Solution features a robust Hot Bar Iron that allows for reflow of solder paste - ideal for flex circuit attach applications.

Our Hot Bar Soldering Solutions feature a proprietary Thermal Feedback loop; far superior to other like equipment as it places the thermal couple directly on the hot bar tip. The solution offers easy to use controls for setting and reviewing temperature curve charts. The system also features a cooling cycle that allows for liquidous solder to solidify prior to the hot bar releasing the product.

System specifications:

AXIS: 3

X AXIS 200mm Stroke

Y AXIS 200mm Stroke

Z AXIS 50mm Stroke

TEACHING METHOD: "Point and Teach" Teaching Pendant

BACK-UP: USB

TEMPERATURE RANGE: 50-500°C

In-line solutions are available with Vision Packages for dynamic alignment, full or partial safety enclosures, single, dual-tip or quad-tip hot irons, and a variety of other options. Contact us today to find out more!

Hot Iron systems are available in a variety of different mounting styles.

.:. Combined with either a: 150 Watt power supply or 180 Watt power supply, users can custom tailor solutions specific to their soldering application requirements.

.:. Additional automatic solder feeding stations can be offered for seamless operation/integration.

.:. Each of our Integration Kits includes: Industrial Grade Power Supply, High Performance Soldering Iron, High Precision Solder Feeding Station, Solder Tip Cleaning Station and Integration Cable Bundle.

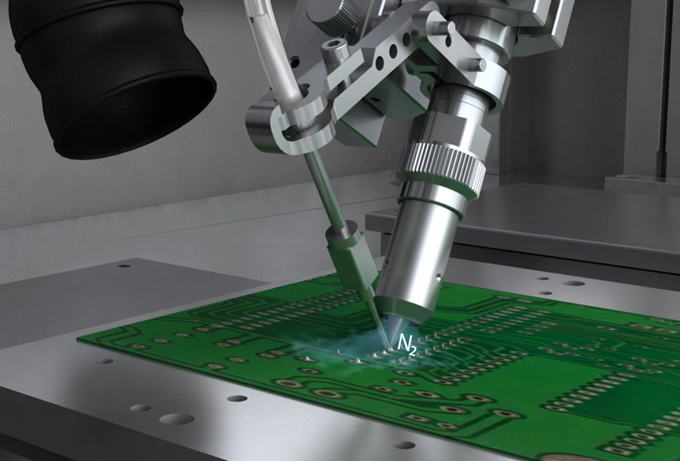

Our Heated Nitrogen Output Kit offers perfect Lead-Free solder joints every time! The Nitrogen Output Kit includes: Table-top Nitrogen Generator, Upgraded BMT Soldering Iron, and Assorted N2 Iron Sleeves.

The system is designed to pump Nitrogen from the Generator towards the solder tip while simultaneously heating the nitrogen using the ambient temperature of the solder tip.

The Table-top N2 Generator creates Nitrogen at a 99.9% Purity out of the ambient air; reducing ongoing consumable costs. No longer is there a need for large supply orders of Nitrogen - we have created a compact solution that is now available across all of our Robotic Soldering Platforms.

System Features:

BMT Soldering Iron Features a closed loop sensor, rapid heating, precise and stable temperature.

Integrated Nitrogen Output Kit Includes: Table-Top N2 Generator, BMT Soldering Iron, and Assorted N2 Sleeves.

Nitrogen Use can have multiple effects on Lead-Free Soldering, such as: Improved Solder Wetting Performance, Shinier Solder Joints, Prolonged Solder Tip Life, Less Clean Cycles, and Reduced Cycle Time.

Heated Nitrogen Output Kits are now available for all Table-Top and In-Line Soldering Solutions!

Facilities Requirements:

Compressed Air Line (N2 Generator Input)

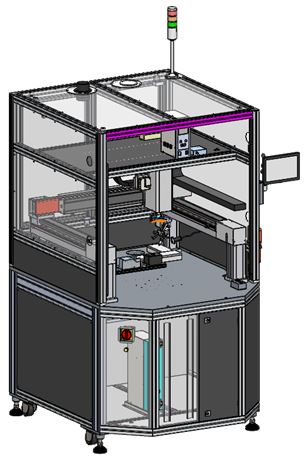

Operator safety remains a top priority. PROMATION USA is proud to offer a variety of different work cell solutions to meet customer specific safety requirement.s Our team specializes in the ability to customize and tailor robot safety enclosures to meet the increasing demands for operator safety; all while offering an elegant and rich exterior- across a variety of robotic work cells. Contact us today to review our complete product offering or to build and customize your very own!

Standard Features:

Dynamic Vision Alignment w/ Vision Mapping

Dual Articulating Robot End-Effector

On-Board Nitrogen Generator w/ Heated N2 Output Kit

High Performance Soldering Technology

PC Based Touchscreen Programming

Process Data Aggregation w/ MES Data Output

And much more…

OPTIONAL FEATURES:

In-Feed Bar Code Scan w/ Auto Recipe Selection

by 700+ customers for 3200+ clients