What are the advantages?

Return on Investment - PROMATION offers the best value in X-Ray Inspection and Component Counting Solutions. Customers often see a ONE YEAR Return on Investment!!

Enhanced Inventory Management - In the fast-paced world of electronics manufacturing, inventory accuracy is crucial for ensuring smooth operations and maximizing efficiency. With the increasing complexity of electronic components, traditional manual methods of inventory management are becoming inadequate. This is where SMD Reel Counter Machines, specifically Seamark's cutting-edge technology, come into play. These machines are revolutionizing component management, improving accuracy, and streamlining processes in the electronics industry.

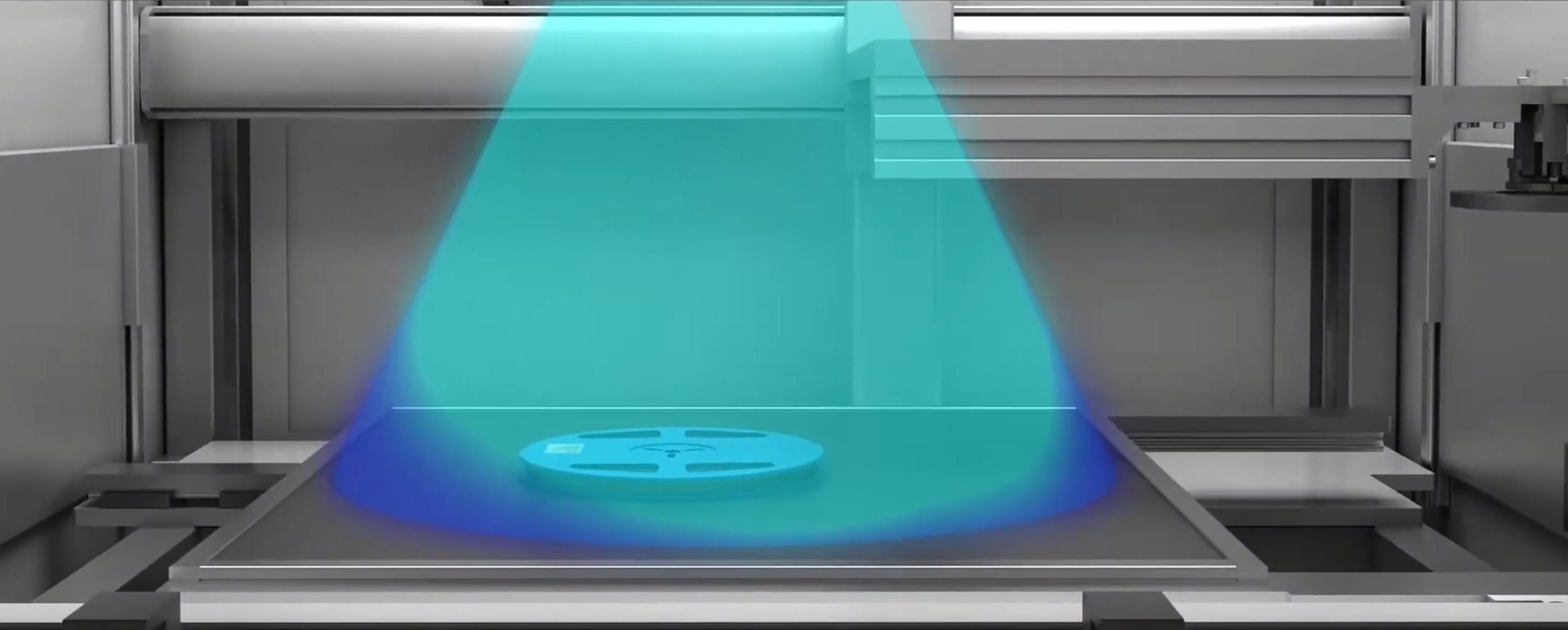

XC-1000 OFfline Reel Counter

The XC-1000 is a micro-focus X-ray full-automatic counting machine.

It uses an X-Ray perspective, and independently developed AI algorithm software, to quickly and accurately calculate the number of materials within the material reel. This X-Ray chip counter also has MES Data upload capability and automatic printing function for material labels. In total, this solution aims to improve work efficiency and improve labor allocation.

Standard Features:

Compared with traditional counting machines, there is no need to unpack or transfer the reel into the X-Ray reel counter.

Suitable for all types of chip components, SMD devices above 01005.

Accuracy of counting reaches more than 99.99%.

Measurable reel diameter is 7-15 inches.

Innovative detection environment and algorithm with AI function.

Realize automatic counting.

Optional Features:

Upgraded Print-on-Demand Printer

by 700+ customers for 3200+ clients